Often described as a material that is mostly air, aerogel represents one of the most remarkable achievements in modern materials science. Despite its extremely low density, aerogel demonstrates exceptional insulating and protective properties, making it valuable across a wide range of scientific, industrial, and commercial applications. From thermal insulation in aerospace and construction to advanced protective equipment, its performance challenges traditional assumptions about strength and weight. At the same time, aerogel presents practical limitations related to cost, durability, and large scale manufacturing. This story examines how aerogel works, where it is currently being used, and why it continues to attract attention from researchers and engineers worldwide. By focusing on real world applications and balanced analysis rather than novelty alone, it offers an accessible introduction to a material that is quietly reshaping how industries approach insulation, efficiency, and lightweight design.

The Astonishing Nature of Aerogel: An Ultralight Solid

When I first held a piece of aerogel in my hand, I was struck by how impossibly light it felt. Aerogel is, quite simply, the lightest and lowest density solid in the world. With a composition that is 99% air and only about 1% solid material, aerogel’s density can be as low as 0.0011 g/cm³. This ultralightweight property is at the heart of many aerogel applications, especially where weight savings are crucial.

Physical Fragility and Transformation

Despite its ethereal appearance, aerogel is incredibly fragile. Even a gentle press from my finger is enough to shatter it into thousands of tiny pieces, turning it almost instantly to dust. Yet, this fragility leads to something remarkable. When I take the aerogel dust and apply it to a surface—like my skin—it forms a completely hydrophobic layer. This means it repels water entirely, making the surface 100% waterproof. The hydrophobic properties of aerogel are so strong that aerogel powder can float on water, and even support the ignition of a match above its surface.

Hydrophobicity and Protective Composites

The transformation of brittle aerogel into a dust that still retains its hydrophobic nature is astonishing. This dust can be reconfigured into a non-brittle, foam-like aerogel composite. Such composites are valuable in extreme applications where both protection and ultralightweight materials are needed. The ability to repel water and keep surfaces dry opens up a wide range of aerogel applications, from waterproof coatings to advanced insulation systems.

Shapes, Sounds, and Unique Properties

Aerogels are not limited to one form—they can be molded into various shapes to suit specific needs. Their unique structure also gives rise to unusual acoustic properties. Given that aerogels are 99% air, the sound they make when tapped is unlike any other material. It’s often described as similar to an empty can rapping onto a steel surface—very metallic and hollow. This is a direct result of their high air content and nanoporous structure.

Composition: Amorphous Silica and Nanoporous Structure

So, what exactly is aerogel made of? In most cases, the solid portion is amorphous silica, which forms the structural backbone of the material. This silica makes up just about 1% of the total volume, but it is essential for providing the framework that holds the air in place. The real secret to aerogel’s astonishing properties lies in its nanoporous structure. The pores are only a few nanometers thick—about 1/10,000 the width of a human hair. This intricate network of tiny pores is what gives aerogel its ultra-low density and is crucial for its effectiveness as a thermal insulator.

Thermal Insulation: The Best in the Universe

One of the most celebrated aerogel applications is thermal insulation. Aerogel is the lowest thermal conductive solid known, making it the best insulation material in existence. Its nanoporous structure traps air and prevents heat transfer, allowing it to withstand extreme temperatures. In fact, aerogel has been tested to insulate against flame temperatures of approximately 1200 degrees Celsius. This is why NASA uses aerogel to insulate spacecraft, including the Mars rovers, where both weight and insulation are critical.

"Aerogel is a really amazing material."

With its combination of ultralightweight properties, hydrophobicity, unique acoustic signature, and unmatched thermal insulation, aerogel stands out as a wonder material. Its nanoporous structure and 99% air composition are at the core of its marvels, enabling a wide range of advanced aerogel applications across industries.

Thermal Insulation Excellence: Aerogel in Spacecraft and Beyond

When it comes to thermal insulation, aerogel stands in a league of its own. As many experts and enthusiasts have noted, "It's the lowest thermal conductive solid in existence or the best insulation in the universe." This remarkable material is not only a scientific marvel but also a practical solution for some of the most demanding environments known to humanity—most notably, space.

Aerogel: The Champion of Low Thermal Conductivity

Aerogel’s claim to fame is its ultra-low thermal conductivity. Its structure is composed of up to 99% air, with the remaining 1% typically being amorphous silica. This unique composition results in a network of nanopores, each only a couple of nanometers thick—about 1/10,000 the width of a human hair. These nanopores trap air and drastically restrict heat transfer, making aerogel the ultimate barrier against both heat and cold.

Aerospace Applications: NASA’s Trusted Insulator

Aerogel’s insulation properties make it indispensable for aerospace applications. NASA has relied on silica aerogel to insulate spacecraft, including the Mars rovers, protecting sensitive instruments from the extreme conditions of space. In these environments, temperatures can swing from the searing heat of direct sunlight to the frigid cold of shadowed craters or deep space. Silica aerogels, which currently hold a 55.3% market share in the aerogel industry, are favored for their superior thermal insulation and lightweight nature—both critical for space missions.

Extreme Heat and Cold: Real-World Testing

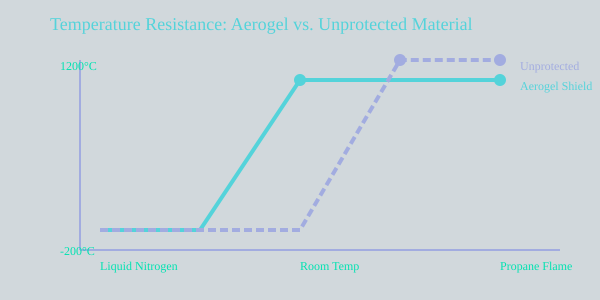

The effectiveness of aerogel is not just theoretical. In practical demonstrations, aerogel shields have been exposed to direct flame from a propane torch, reaching temperatures around 1200°C. Even under these intense conditions, the material allows minimal heat penetration, keeping the protected side cool enough to touch. On the other end of the spectrum, aerogel can withstand exposure to liquid nitrogen at -196°C, further proving its versatility in extreme thermal environments.

Aerogel shields withstand 1200°C with minimal heat penetration.

Beyond Space: Potential for Buildings and Apparel

Given its outstanding insulation, it’s natural to ask: why isn’t aerogel used everywhere, from building insulation to thermal apparel? The answer lies in its mechanical properties. Traditional aerogels are extremely brittle, which limits their use in many commercial applications. However, recent innovations in flexible aerogels and composite materials are addressing this challenge. By combining aerogel with closed cell foams or reinforcing fibers, manufacturers are creating materials that retain aerogel’s insulation while offering improved strength and flexibility—making them suitable for use in apparel and construction, especially in extreme conditions.

Challenges and Ongoing Innovations

Despite its remarkable properties, the brittleness of aerogel has been a significant barrier to widespread adoption. As one researcher put it, “The challenge with aerogel, since the beginning of time, has been that this stuff is super brittle.” Companies like Oro Labs are pioneering solutions by developing flexible aerogel composites, opening the door for broader applications and making the most of this ultrathin wonder material in both aerospace and everyday life.

Transforming Fragility: Innovations in Aerogel Composites

When I first encountered aerogel, I was amazed by its ultralight structure and remarkable insulation properties. However, like many others, I quickly realized its biggest drawback: extreme brittleness. As one expert put it,

"The challenge with aerogel since the beginning of time has been that this stuff is super brittle."

This fragility has long limited aerogel’s use in practical applications, especially where mechanical strength and flexibility are essential.

Traditional Aerogel: A Brittle Marvel

Aerogel’s unique structure—composed of up to 99% air—makes it an outstanding insulator, but also leaves it prone to cracking and breaking under stress. This brittleness means pure aerogel can’t easily withstand the rigors of daily use, especially in demanding environments like construction or protective gear. For years, this has been the main barrier to its mainstream adoption.

Closed-Cell Foam Composites: A Breakthrough in Mechanical Strength

To address this challenge, innovators at companies like Oro Labs and Solarcore have developed a new class of aerogel composites. By embedding aerogel within a closed-cell foam matrix, they have created materials that combine the best of both worlds: the thermal and hydrophobic properties of aerogel, and the mechanical resilience of foam.

Closed-cell foams are made from a silica-based substance, structured with countless tiny, sealed air pockets. These pockets not only trap air for insulation but also provide a cushion that absorbs impacts and resists deformation. The result is a composite that maintains aerogel’s low thermal conductivity while dramatically improving its durability and flexibility.

Testing the Limits: From Flames to Freezing Temperatures

The performance of these new flexible aerogels is impressive. In demonstrations, the composites have been subjected to direct flame exposure and mechanical impacts. The results speak for themselves: the material resists breakage, does not melt, and maintains its insulating properties even under extreme conditions. For example, these composites can withstand temperatures ranging from -196°C to 1200°C, a range that covers everything from cryogenic storage to high-temperature industrial processes.

During one test, a sample of the aerogel composite was exposed to a flame. While the surface in contact with the flame became hot, the opposite side remained cool enough to touch. This dramatic difference highlights the material’s ability to block heat transfer, even in the most demanding situations.

Expanding Applications: From Construction to Apparel

The enhanced mechanical strength of these aerogel composites opens up a world of new possibilities. In construction, they can be used as advanced insulation panels that are not only energy-efficient but also tough enough to handle installation and long-term use. In the apparel industry, flexible aerogels are finding their way into protective gear and outdoor clothing, offering lightweight warmth without the risk of the material crumbling or breaking.

Construction materials: Durable, high-performance insulation for walls, roofs, and windows.

Protective gear: Lightweight, impact-resistant padding for gloves, jackets, and helmets.

Extreme conditions: Equipment and clothing designed for space, arctic, or industrial environments.

Leading the Way: Oro Labs and Solarcore

Companies like Oro Labs and Solarcore are at the forefront of this transformation. By focusing on composite structures and advanced reinforcement—such as carbon fiber—they have managed to preserve aerogel’s core benefits while overcoming its traditional weaknesses. Their innovations are setting new standards for what’s possible with ultrathin, high-performance materials.

As the technology matures, I expect to see even broader adoption of these advanced aerogel composites, especially in fields where both insulation and mechanical strength are critical.

Aerogel’s Surprising Waterproof and Hydrophobic Powers

When it comes to aerogel applications, one of the most fascinating features is its remarkable hydrophobic properties. Aerogel, especially in its powder form, can create a completely waterproof barrier when applied to the skin. This is not just a theoretical claim—real-world demonstrations show that aerogel dust acts as an invisible shield, keeping water at bay even in the most challenging conditions.

Hydrophobic Aerogel Powder: Floating on Water

To truly understand the power of waterproof aerogel, consider a simple experiment: sprinkle aerogel powder onto the surface of water. Instead of sinking, the powder floats, forming a visible barrier between itself and the liquid. This floating effect is a direct result of aerogel’s unique nanoporous structure and surface chemistry, which actively repels water molecules. The powder doesn’t absorb or mix with the water; it remains dry and buoyant, a clear demonstration of its hydrophobic nature.

Creating a Waterproof Barrier on Skin

Applying aerogel dust directly to the skin takes this concept even further. When I covered my hand with aerogel powder and submerged it in water, the results were astonishing. Water formed ball-shaped droplets that simply rolled off, never actually touching my skin. There was a distinct layer of aerogel between my skin and the water, and even after full immersion, my hand was completely dry. As I described in the moment,

"I am dry. This is miracle guys."

This effect isn’t limited to small areas. By covering my entire body with aerogel powder and submerging myself in a pool, I stayed dry even underwater. The aerogel particles blocked water from reaching my skin, and I didn’t feel cold at all. The sensation was almost magical—like wearing an invisible, weightless wetsuit.

The Science Behind Aerogel’s Hydrophobicity

The secret to aerogel’s waterproof properties lies in its nanoporous structure. Aerogel is made up of a network of tiny pores, each smaller than a wavelength of visible light. These pores trap air and prevent water molecules from passing through. When submerged, aerogel can even create a silvery glow underwater, caused by light scattering off the trapped air bubbles—a phenomenon that’s both beautiful and scientifically intriguing.

Applications in Protective Apparel and Extreme Environments

The ability of hydrophobic aerogel to repel water and provide thermal insulation makes it ideal for protective clothing and gear. In extreme environments—whether it’s freezing cold or soaking wet—apparel lined with aerogel can keep the wearer dry and comfortable. This is especially valuable for outdoor adventurers, emergency responders, and anyone exposed to harsh weather conditions. The unique feeling of dryness and warmth, even when surrounded by water, is a testament to aerogel’s potential in wearable technology.

Hydrophilic Aerogels: The Opposite Approach

Not all aerogels are hydrophobic. Hydrophilic aerogels are engineered to absorb moisture, making them perfect for controlling humidity in sensitive environments. For example, museums and medical storage facilities use hydrophilic aerogels to protect valuable artifacts and medicines from excess moisture. These aerogels can absorb up to 25 times their weight in water, demonstrating the versatility of aerogel technology depending on its surface chemistry.

Visual and Sensory Effects

One of the most striking visual effects of waterproof aerogel is the silvery sheen seen underwater, caused by the way aerogel traps air and reflects light. On the skin, aerogel powder feels dry and insulates against both heat and cold, adding another layer of protection in extreme conditions. Whether used as a floating powder, a protective coating, or an insulating layer, aerogel’s hydrophobic properties open up a world of innovative applications.

Light, Color, and Optical Phenomena: Why Aerogel Looks Blue and Changes Under Light

One of the most fascinating aspects of aerogel is how it interacts with light. Its unique nanoporous structure—with pores much smaller than the wavelengths of visible light—gives rise to remarkable optical properties. These properties not only define aerogel’s appearance but also open up possibilities for advanced applications, especially where light scattering and photoprotective properties are important.

Aerogel’s Nanopores: Smaller Than Visible Light Wavelengths

To understand why aerogel looks the way it does, we need to look at the scale of its pores compared to visible light. Visible light has wavelengths ranging from 380 to 750 nanometers (nm). In contrast, the pores in aerogel are only about 20 to 40 nm wide. This means that the pores are much smaller than any color of visible light. This size difference is crucial because it determines how light interacts with the material.

Rayleigh Scattering: The Science Behind the Blue Hue

When light passes through a material with such tiny pores, the shorter wavelengths—such as blue and violet—are scattered more strongly than the longer red wavelengths. This phenomenon is known as Rayleigh scattering. As I often explain,

"Aerogel looks blue for the same reason the sky does — Rayleigh scattering."

The sky appears blue because the atmosphere scatters shorter wavelengths of sunlight more efficiently, and aerogel’s nanoporous structure creates a similar effect. When white light hits aerogel, the blue and violet components are scattered in all directions, making the material appear blue to our eyes.

Optical Changes Under Different Light Sources

Ultraviolet (UV) Light: UV light has even shorter wavelengths than visible blue light. When aerogel is exposed to UV, the scattering is even stronger. This makes the aerogel appear opaque under UV light, as the intense scattering prevents the light from passing through.

Infrared (IR) Light: On the other end of the spectrum, infrared light has much longer wavelengths. These longer wavelengths are not scattered by the tiny pores and can pass through aerogel with little resistance. As a result, aerogel appears completely transparent under infrared light.

Sunlight: In natural sunlight, which contains a mix of all visible wavelengths, aerogel can sometimes appear yellow. This happens because some blue light is scattered out, and the remaining transmitted light is richer in yellow and red wavelengths.

Color Effects and Photoprotective Properties

The way aerogel interacts with different wavelengths of light is more than just a visual curiosity. These optical properties can be harnessed for practical uses. For example, the strong scattering of UV and blue light means aerogel can act as a photoprotective barrier, shielding sensitive equipment or materials from harmful radiation. Its transparency to infrared light also makes it valuable in applications where heat transfer is needed without visible light transmission.

Identity Beyond Insulation: Aerogel’s Optical Signature

These color and light effects are a direct result of aerogel’s nanoporous structure and are key to identifying genuine aerogel. The blue tint, the shift to opacity under UV, and the transparency in infrared all stem from how light scatters within the material. This optical signature gives aerogel a unique identity, distinguishing it from other insulators and materials. As research advances, these aerogel properties are being explored for new technologies, from photoprotective coatings to advanced sensors, making the most of its remarkable light scattering abilities.

Why Isn't Aerogel Everywhere? The Market Challenge and Future Outlook

Whenever I talk about aerogel and its incredible thermal insulation properties, one question always comes up: If aerogel is so good—used to insulate spacecraft and protect against extreme temperatures—why don’t we see it everywhere on Earth? From buildings to jackets, it seems like aerogel should be the go-to material. But as I’ve learned, there’s one major problem holding it back: brittleness. Let’s look at the market challenges and what the future holds for this ultrathin wonder material.

Brittleness: The Main Barrier to Mass Adoption

Despite its excellent thermal insulation, traditional aerogel—especially silica aerogel—is extremely brittle. This fragility makes it difficult to use in applications where flexibility and durability are needed, such as in building insulation or wearable apparel. If you try to bend or compress a classic aerogel panel, it can crack or crumble, which is a clear disadvantage compared to other insulation materials.

Innovations in Flexible and Composite Aerogels

Researchers are actively working to overcome aerogel’s mechanical limitations. Recent advances include the development of flexible aerogels and composite materials. By reinforcing silica aerogels with fibers or combining them with polymers, scientists have created aerogels that are much less brittle and more suitable for real-world use. As one industry report notes:

"Innovations include fiber-reinforced and bio-based aerogels improving durability and sustainability."

These new flexible aerogels are already increasing their share in the aerogel market, making them more appealing for construction, apparel, and even automotive uses.

Production and Cost Challenges

Another significant hurdle is the cost and complexity of producing aerogel at scale. The manufacturing process is energy-intensive and requires specialized equipment, which drives up prices. For many building projects or consumer products, traditional insulation materials like fiberglass or foam are simply much cheaper and easier to install.

Mass production methods are improving, but cost efficiency remains a barrier to widespread adoption. As demand grows and manufacturing technology advances, prices are expected to come down, making aerogel more competitive in the future.

Market Demand and Growth Sectors

Despite these challenges, the aerogel market is growing, especially in sectors where performance matters most. Aerospace, construction, and energy industries value aerogel for its unique combination of light weight and high thermal insulation. According to Coherent Market Insights, silica aerogels are expected to hold a 55.3% market share by 2025, mainly due to their stability and insulation properties.

Temperature resistance: Aerogels can withstand temperatures from -196°C to above 1200°C, making them ideal for extreme environments.

Energy efficiency: As regulations push for better energy performance in buildings, demand for high-performance insulation like aerogel is rising.

Sustainability and Bio-Based Aerogels

There’s also a growing focus on sustainability. Bio-based aerogels, made from renewable materials like cellulose or chitosan, are being developed to reduce environmental impact. These eco-friendly options could open new markets and help meet stricter environmental regulations.

Composite aerogels that blend silica with carbon fibers or plant-based materials are another promising direction. They offer improved mechanical strength and a lower carbon footprint, which is increasingly important for green building standards.

The Future Outlook for the Aerogel Market

With more research into flexible and bio-based aerogels, and with energy efficiency regulations becoming stricter worldwide, the aerogel market is expected to grow significantly. While brittleness and cost are still challenges, ongoing innovations are steadily expanding aerogel’s role in thermal insulation and beyond.

Unexpected Experiments: Fire, Ice, and the Human Element with Aerogel

When it comes to extreme conditions, few materials have captured the imagination of scientists and explorers like aerogel. My own hands-on experiments with this ultralight wonder material have revealed just how powerful its thermal insulation properties are, especially when put to the test against fire, ice, and even full-body immersion. These demonstrations not only showcase the science behind aerogel but also highlight its real-world potential in protective gear and thermal apparel.

To truly understand what aerogel can do, I decided to test its limits with some of the harshest elements. First, I placed an aerogel shield directly in the path of a propane flame, which burns at an average temperature of about 1,200 degrees Celsius. As the flames roared, I could feel some heat from the side, but, remarkably, there was nothing from the center. The aerogel held strong, and I was able to touch the shield even while it was exposed to the intense heat. As I said in the moment,

"I can still touch it."

This simple act demonstrated the incredible thermal barrier that aerogel provides, making it an ideal candidate for protective equipment in environments where high temperatures are a constant threat.

But aerogel’s abilities are not limited to heat. I wanted to see how it would perform against the opposite extreme: liquid nitrogen, which sits at a bone-chilling -196 degrees Celsius. To illustrate the danger, I first exposed unprotected materials to liquid nitrogen. The results were dramatic—organic materials like parsley and chicken froze instantly, shattering with just a touch. This highlighted how dangerous such cold can be to unprotected skin, as even brief contact could cause severe injury.

The real test came when I donned a jacket insulated with aerogel and faced a direct spray of liquid nitrogen. As the vapor enveloped me, I braced for the cold, but to my surprise,

"I don't feel it. Just on my pants."

The aerogel composite shielded my skin, preventing the freezing effect and keeping me safe. This experiment underscored aerogel’s dual ability to protect against both burning and freezing—an essential feature for aerogel applications in extreme environments.

Curiosity pushed me further. I wanted to know if aerogel could keep me dry and insulated underwater. I coated my body with powdered silica aerogel, creating a thin, hydrophobic barrier. When I submerged myself in icy water, the results were astonishing. Not only did I remain dry, but the aerogel layer trapped a silvery sheen of air bubbles against my skin. This effect, both visually striking and scientifically significant, provided buoyancy and insulation, keeping the cold at bay. As I emerged, I realized,

"I am dry. This is miracle guys."

The particles blocked water from reaching my skin, demonstrating aerogel’s promise for waterproof and insulating clothing.

Throughout these experiments, careful safety checks were essential. Each demonstration was designed to push the boundaries of what lightweight materials like aerogel can achieve, while ensuring no harm came to anyone involved. The emotional and visual impact of these tests—whether it was the shimmering air bubbles or the thrill of standing unharmed in the face of fire and ice—brought the science of aerogel to life.

These unexpected experiments reveal more than just the technical marvels of aerogel; they showcase its potential to revolutionize protective apparel and gear for those who work or explore in the world’s most extreme conditions. From withstanding the searing heat of a propane flame to defying the freezing touch of liquid nitrogen, aerogel stands out as a material that could redefine safety and comfort in challenging environments. As we continue to explore and innovate, aerogel’s role in the future of thermal insulation and aerogel applications is only just beginning.