3D scanning technology has rapidly evolved from specialized industrial equipment into a versatile tool used across design, manufacturing, healthcare, architecture, and creative industries. Modern scanners are capable of capturing highly detailed digital models of physical objects, enabling faster prototyping, accurate measurements, and seamless integration into digital workflows. With a growing variety of handheld, desktop, and industrial-grade systems available, selecting the right 3D scanner requires understanding key factors such as accuracy, scanning speed, portability, software compatibility, and intended application. This guide explores the essential features that distinguish high-performing scanners, explains how different technologies suit different professional and creative needs, and highlights practical considerations for long-term usability. Rather than focusing only on specifications, it emphasizes real-world performance and workflow efficiency, helping readers choose a 3D scanning solution that supports both current projects and future innovation.

The Marvel of Modern 3D Scanners: An Overview

Imagine being able to capture the exact shape and details of any object—big or small—at the push of a button. That’s the promise of the best 3D scanners today. From home DIYers to industrial engineers, these devices have become essential tools for turning real-world objects into precise digital models. Over the years, 3D scanning technology has evolved from bulky, complex machines to sleek, portable devices that anyone can use. This section explores how modern 3D scanners work, their innovative features, and why they’re now a staple in so many fields.

How 3D Scanners Work: From Lasers to Hybrid Innovations

At their core, 3D scanners use light to measure the shape of objects. Early models relied on a single technology, but the latest scanners combine multiple methods for superior results. Hybrid scanning technologies —like blue laser scanning combined with structured light—are leading the way. As Dr. Helen Thompson, a 3D Imaging Specialist , puts it:

“The blend of laser and structured light is changing how precise measurements can be captured quickly.”

For example, the Revopoint MetroX uses both blue laser and structured light technology to achieve metrology-grade precision of up to 0.01 mm. This hybrid approach means you get the best of both worlds: the fine detail of laser scanning and the speed of structured light.

Leading Brands and Standout Models

Some brands have set the standard for performance and reliability. The FARO Focus Premium is a powerhouse, scanning up to 2 million points per second with a reach of 350 meters—ideal for large construction sites or industrial plants. Meanwhile, portable models like the Revopoint POP 3 Plus offer 0.04 mm precision in a device you can carry anywhere, perfect for fieldwork or quick prototyping.

Real-World Uses: From Hobbyists to Industry Giants

3D scanners are no longer just for engineers. Hobbyists use them for custom car parts, artists for sculpture digitization, and educators for interactive learning. In professional settings, they’re vital for reverse engineering , quality control, and even preserving historical artifacts. Michael Lee, a tech innovator, says:

“Modern 3D scanners empower industries from manufacturing to archaeology; the possibilities are endless.”

In construction, integration with Scan to BIM workflows is making project planning faster and more accurate than ever before.

Smart Features: Simpler, Faster, More Accurate

Today’s best 3D scanners come packed with features that make scanning easier for everyone. Real-time feedback shows you if you’ve missed a spot, while marker-less scanning means you don’t need to stick targets on your object. Portable models let you scan on-site, whether you’re documenting a building or capturing a rare artifact in the field.

With these advances, 3D scanning is now as accessible as taking a photo—only with much more detail and endless possibilities for creativity and precision.

Key Features & Benefits: What Makes These 3D Scanners Stand Out?

When it comes to choosing the best 3D scanners in 2026, it’s all about the perfect blend of metrology-grade precision , speed, and user-friendly design. Whether you’re an engineer, designer, hobbyist, or construction professional, these advanced devices are changing how we capture and recreate the world in digital form. But what exactly sets the latest 3D scanners apart? Let’s dive into the key features and benefits that make these tools indispensable for both everyday and specialized needs.

Metrology-Grade Precision: Pinpoint Accuracy for Every Project

Modern 3D scanners now deliver metrology-grade precision —with accuracy ranging from a remarkable 0.01 mm to 0.04 mm, depending on the model. For example, the Revopoint Mini achieves an impressive 0.02 mm accuracy, making it ideal for small parts inspection or jewelry design. This level of detail ensures that every scan is reliable enough for industrial metrology, reverse engineering, or even delicate restoration work.

“Precision is not just about numbers, but about making 3D scanning accessible and reliable.” – Tom Baker, Product Developer

Advanced Scanning Technologies: Blue Laser, Structured Light, and Infrared

Today’s scanners use a variety of technologies to suit different needs. Blue laser scanners excel in capturing fine details and shiny surfaces, while structured light systems are perfect for fast, high-resolution scans of objects large and small. Infrared cameras, as seen in the Revopoint MIRACO Plus , enable safe, efficient scanning of people and sensitive materials. Many models, like the Revopoint MIRACO Plus , even combine quad-camera infrared with photogrammetry for unmatched versatility.

High-Speed Scan Rates: From Tiny Objects to Massive Structures

Speed matters, especially when scanning large areas or working under tight deadlines. Devices like the Leica ScanStation P50 offer scan rates that make it possible to digitize entire buildings or landscapes—boasting a range of over 1 km. Meanwhile, portable handheld scanners can capture smaller objects in seconds, making them perfect for rapid prototyping or fieldwork.

Portability & Real-Time Usability: Scan Anywhere, Anytime

Portability is a game-changer. Handheld models like the Revopoint Mini and mobile apps such as Polycam transform 3D scanning from a lab-bound task to an on-site solution. You can scan artifacts in a museum, inspect machinery in a factory, or capture a room layout for BIM workflows—all with real-time feedback and onboard editing.

“Portability transforms scanning from a lab task to an on-site solution.” – Sarah Mitchell, Field Engineer

Seamless Workflow Integration: BIM & Industrial Compatibility

Modern scanners are designed to fit right into your workflow. Export formats like OBJ and STL (supported by Polycam and Scaniverse ) make it easy to use your scans in CAD, 3D printing, or Building Information Modeling (BIM) software. This compatibility streamlines everything from industrial inspection to creative design.

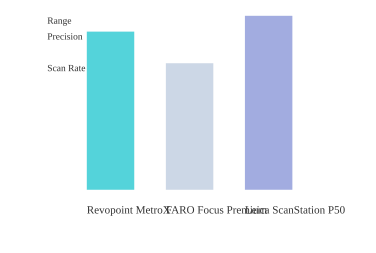

Professional Comparison Chart

As you can see, each scanner excels in different areas—whether it’s ultra-fine precision, rapid scan rates, or long-range capabilities—offering a solution for every scanning challenge.

Pros and Cons: Weighing the Strengths and Limitations

When exploring the best 3D scanners of 2026, it’s important to look at both the strengths and the limitations. Whether you’re a hobbyist, a professional designer, or someone working in construction or healthcare, understanding the reasons to buy and reasons to avoid certain models will help you make a smart investment. As Elaine Ramirez, Industry Consultant, wisely puts it:

“No technology is perfect; choosing the right scanner means matching needs with capabilities.”

Pros: Why Choose High Accuracy 3D Scanners?

Incredible Precision at Sub-Millimeter Levels

Many high accuracy 3D scanners deliver detail down to fractions of a millimeter. This is essential for applications like dental modeling, jewelry design, and reverse engineering. For example, an artist can capture every curve of a sculpture, or a mechanic can recreate a rare car part with confidence.Hybrid and Multi-Camera Systems Offer Rich Data Capture

Advanced models use multiple cameras and hybrid sensors (like structured light and laser) to gather more data in a single scan. This means fewer blind spots and more reliable results, even on complex objects with tricky angles.Portability Enables Scanning in Challenging Environments

Many modern scanners are lightweight and battery-powered, making them easy to use on construction sites, archaeological digs, or even outdoors. For example, a contractor can scan a building facade without bulky equipment, or a museum curator can digitize artifacts on location.Real-Time Feedback Improves User Experience

Some scanners provide instant visual feedback, helping users adjust their technique and avoid errors. This feature is especially helpful for beginners and speeds up the learning process.

Cons: Reasons to Avoid or Consider Carefully

High-End Models Can Be Expensive and Demand Training

Professional-grade 3D scanners often come with a hefty price tag and require specialized training to use effectively. For small businesses or casual users, this can be a significant barrier.Larger Scanners Lack Portability and Require Specialized Setups

While some scanners are compact, others are large and need stable mounts or controlled environments. This makes them less practical for fieldwork or scanning large objects on the go.Environmental Factors Like Lighting and Surface Texture Impact Accuracy

Even the best 3D scanners can struggle with shiny, transparent, or dark surfaces. Bright sunlight or inconsistent lighting can also affect scan quality, requiring careful setup or additional equipment.Learning Curve and Complexity

While user experience is improving, there’s still a learning curve—especially for advanced features or software. Beginners may need time to master the process.

Ultimately, the best 3D scanner for you depends on your unique needs, budget, and environment. Tradeoffs between portability, precision, and range are common, so weigh these reasons to buy and reasons to avoid carefully before making your choice.

Best Use Cases and Who Should Buy Them?

When it comes to BEST 3D Scanners , the right choice depends on your specific needs, industry, and workflow. From industrial metrology to creative arts, 3D scanners have found their place in a wide range of applications. As Anil Kumar, a construction tech expert, wisely puts it:

“Selecting a scanner depends on the project scale, environment, and output needs.”

Industrial Metrology & Quality Control

For industries like automotive, aerospace, and manufacturing, precision is non-negotiable. Scanners such as the Revopoint MIRACO Plus are engineered for high accuracy, making them perfect for industrial metrology , quality control, and inspection. These devices capture fine details and tight tolerances, ensuring that every component meets strict standards. If your work involves checking the dimensions of machined parts or verifying product consistency, this category is your best fit. Check latest price here .

Construction & Large-Scale Scanning

Construction professionals and surveyors often need to scan large areas, buildings, or infrastructure. Devices like the Leica BLK360 and NavLive Radius are top choices for best construction scanners due to their long-range capabilities and seamless integration with BIM workflows. These scanners are invaluable for site documentation, progress tracking, and clash detection. Their portability is a huge plus for field engineers and on-site inspections. See customer reviews here .

Creative Arts, DIY, and Education

Artists, designers, and hobbyists benefit from portable, user-friendly handheld scanners like the Revopoint POP 3 Plus . These are ideal for scanning sculptures, small objects, or even people. Their ease of use and affordability make them accessible for classrooms, makerspaces, and personal projects. If you want to digitize collectibles or create custom 3D models, this is your go-to option. Check latest price here .

Reverse Engineering & Product Design

Reverse engineering requires capturing intricate details and complex geometries. Blue laser and structured light scanners excel here, delivering high-resolution scans suitable for CAD modeling and product redesign. Engineers and designers in industries like automotive restoration or product prototyping will appreciate the accuracy and versatility these scanners offer.

Scanning Large Spaces

For mapping entire buildings, warehouses, or archaeological sites, devices like the FARO Focus Premium stand out. With high scan rates and extended reach, they efficiently capture vast environments in detail. These are essential for architects, civil engineers, and heritage preservation teams who need comprehensive spatial data.

Quick, Casual 3D Captures

Mobile app-based scanners are perfect for quick, on-the-go 3D captures. While they lack the detail required for professional use, they’re handy for casual users, educators, or anyone needing a fast digital copy of an object.

In summary, scanner selection is deeply linked to intended application and professional requirements . Whether your target use is industrial metrology, construction, creative projects, or large-scale mapping, there’s a 3D scanner designed for your needs.

How to Choose the Right 3D Scanner: A Simple Guide

Choosing the best 3D scanner can feel overwhelming, especially with so many options available in 2026. Whether you’re a hobbyist, a professional designer, or a business owner, the right scanner can transform your workflow, boost accuracy, and open up new creative possibilities. Here’s a straightforward guide to help you match your needs with the perfect 3D scanner—without getting lost in technical jargon.

1. Evaluate Required Precision and Accuracy

Before diving into features, ask yourself: How precise do my scans need to be? If you’re capturing small mechanical parts for engineering or dental models, a high precision 3D scanner is essential. For general art, gaming, or VR projects, moderate accuracy might suffice. Always check the scanner’s accuracy rating (usually in microns or millimeters) and compare it to your project requirements.

2. Consider Object Size and Scanning Environment

Think about the typical size of objects you’ll scan. For large objects or outdoor environments, a portable handheld 3D scanner offers flexibility and ease of use. For tiny, intricate items, a desktop or tripod-mounted scanner may deliver better results. Also, consider if you’ll be scanning in a studio, on-site, or in varying light conditions—some scanners handle bright sunlight or low light better than others.

3. Assess Technology Types: Blue Laser, Structured Light, LiDAR, Infrared

Different scanning technologies suit different tasks:

Blue Laser: Excellent for high precision and shiny or dark surfaces.

Structured Light: Great for capturing fine details and color, ideal for objects with complex textures.

LiDAR: Best for large-scale environments, like rooms or buildings.

Infrared: Often used in affordable, portable models—good for quick, rough scans.

Hybrid models combine these technologies but may come at a higher price.

4. Determine Budget and Maintenance Costs

Set a realistic budget, factoring in not just the initial price but also ongoing costs like calibration, software updates, and replacement parts. Sometimes, a slightly higher upfront investment in a reliable scanner saves money and headaches down the road.

5. Check Software Compatibility

Make sure the scanner’s software integrates smoothly with your workflow—whether you use BIM, CAD, or 3D printing platforms. Some scanners come with user-friendly apps for mobile-powered scanning, making them ideal for fieldwork or on-the-go projects.

6. Prioritize Features That Matter to You

Do you need real-time feedback or onboard editing? Some models offer instant mesh previews and basic editing tools, which can speed up your process. Test these features if possible before buying.

“Don’t just buy the flashiest scanner—focus on your actual scanning needs.” – Linda Park, 3D Solutions Advisor

By matching scanner capabilities to your needs and budget, you’ll ensure satisfaction and get the most value from your investment.

Maintenance & Care: Keeping Your 3D Scanner in Top Shape

Investing in one of the best 3D scanners is a smart move for anyone who values precision and innovation—whether you’re a designer, engineer, educator, or hobbyist. But to truly get the most out of your scanner and protect your investment, routine maintenance tips and proper 3D scanner care are essential. As Roberto Silva, a seasoned scanner technician, wisely says:

“Proper care can make the difference between a glance and a lifetime of accurate scans.”

Regular Cleaning: The First Line of Defense

Just like camera lenses, the optical components of your 3D scanner are sensitive to dust, fingerprints, and smudges. Over time, even tiny particles can degrade scan accuracy. Make it a habit to gently clean the lenses and sensors using a microfiber cloth and, if recommended, specialized cleaning solutions. For example, after scanning a clay model in a studio, a quick wipe can prevent residue build-up that might affect your next project.

Proper Storage: Protecting Delicate Parts

When not in use, always store your scanner in a dedicated case or a dust-free environment. This is especially important for portable and handheld models, which are more likely to be exposed to accidental bumps or environmental hazards. Think of your scanner like a musical instrument—proper storage preserves its “tune” and performance.

Periodic Calibration: Ensuring Ongoing Accuracy

Even the most advanced 3D scanners require periodic calibration to maintain their measurement reliability. Most manufacturers provide clear guidelines, and some models even offer self-calibration features to simplify the process. For example, if you notice slight inconsistencies in your scans, recalibrating can quickly restore peak performance. Always follow your device’s manual for best results.

Software & Firmware Updates: Staying Up-to-Date

Manufacturers frequently release updates that improve functionality, add new features, or fix bugs. Regularly updating your scanner’s software and firmware ensures you benefit from the latest enhancements and security patches. It’s a simple step that can make a big difference in your daily workflow.

Gentle Handling: Preventing Physical Damage

Handheld 3D scanners are designed for mobility, but they’re not immune to drops or rough handling. Always use wrist straps if available, and avoid placing the device on unstable surfaces. Treat your scanner with the same care you’d give a high-end camera or smartphone.

Environmental Controls: Minimizing Dust & Temperature Extremes

Extreme temperatures and dusty environments can harm sensitive electronics and optics. If you’re scanning outdoors or in a workshop, try to minimize exposure to direct sunlight, moisture, and airborne particles. Using covers or working in controlled spaces can extend your scanner’s operational life.

Remember, every model is unique—always consult your scanner’s manual for model-specific maintenance tips and care instructions tailored to your lifestyle and working environment. With a little attention, your 3D scanner will deliver accurate, reliable results for years to come.

Final Verdict & Recommendations: Which 3D Scanner Deserves Your Investment?

Choosing the Best 3D Scanner Overall in 2026 comes down to a careful balance of precision, portability, and price. With so many options on the market, it’s easy to feel overwhelmed. To help you decide, I’ve compared the top 3D scanners across different needs and budgets, highlighting real-world performance and user feedback.

Revopoint MetroX : Metrology-Grade Precision for Professionals

If your projects demand the highest accuracy, the Revopoint MetroX stands out as the top choice. With a remarkable 0.01 mm precision and hybrid scanning technology, it’s engineered for professionals in engineering, quality control, and digital fabrication. The MetroX’s ability to capture fine details makes it ideal for reverse engineering, jewelry design, and industrial inspection. Check latest price here .

FARO Focus Premium : The Powerhouse for Large-Scale Scanning

For architects, surveyors, and construction professionals, the FARO Focus Premium is hard to beat. Its scan rate of 2 million points per second and extended range allow you to capture entire buildings or complex sites with impressive speed and accuracy. This scanner is perfect for those who need to document large environments or create precise as-built models. See customer reviews here .

Revopoint POP 3 Plus: Portability Meets Performance

Not everyone needs industrial-grade power. The Revopoint POP 3 Plus offers a fantastic blend of portability and accuracy (up to 0.04 mm), making it a great fit for educators, makers, and small business owners. It’s lightweight, easy to use, and connects seamlessly to laptops or mobile devices—ideal for scanning objects on the go or in the classroom. Check latest price here .

Mobile App Scanners: Quick and Casual Solutions

If you’re a hobbyist or need rapid prototyping, mobile app-based scanners are surprisingly capable. They’re perfect for quick scans, basic 3D modeling, or sharing ideas with clients. While they can’t match the precision of dedicated hardware, their convenience and affordability make them a smart choice for casual users.

Key Considerations Before You Buy

Project Scope: Are you scanning small objects or entire rooms?

Budget: Professional-grade scanners cost more but deliver unmatched accuracy.

Technical Support: Reliable customer service can make a big difference, especially for first-time users.

“The best scanner is the one that feels like an extension of your handiwork.” – Jessica Chen, Digital Fabrication Expert

Ultimately, the right 3D scanner is the one that matches your workflow and aspirations. Whether you need the metrology-grade accuracy of the Revopoint MetroX , the site-spanning reach of the FARO Focus Premium , or the everyday flexibility of the Revopoint POP 3 Plus , there’s a solution tailored for you. For direct browsing and purchase options, affiliate links are provided for your convenience.

FAQ: Answering Your Burning Questions about Best 3D Scanners

Choosing the best 3D scanner can feel overwhelming, especially with so many technical terms and options on the market. To help you make an informed decision, I’ve gathered the most common questions from users and experts about 3D scanning. Whether you’re a hobbyist, designer, or business owner, these answers will clarify what matters most when picking the right 3D scanner for your needs.

What is the difference between blue laser and structured light scanning?

Both blue laser and structured light scanning are popular technologies in the world of 3D scanning, but they work differently. Blue laser scanners use a focused blue laser beam to capture fine details, making them ideal for scanning shiny or dark surfaces, such as metal parts or automotive components. Structured light scanners, on the other hand, project a pattern of light onto the object and use cameras to detect distortions in the pattern. This method is often faster and better for capturing larger objects or those with less reflective surfaces, like sculptures or furniture. In short, blue laser is best for high precision and tricky materials, while structured light is faster and more versatile for general use.

Are handheld 3D scanners accurate enough for professional use?

Yes, many modern handheld 3D scanners are accurate enough for professional applications. Advances in sensor technology and software have made it possible for handheld models to achieve sub-millimeter accuracy, which is suitable for tasks like reverse engineering, quality inspection, and medical modeling. However, the level of accuracy can vary between models, so it’s important to check the specifications and match them to your project’s needs. For extremely high-precision tasks, a stationary or desktop scanner might still be the better choice.

How does scanning range affect the choice of scanner?

Scanning range refers to the maximum distance between the scanner and the object that still allows for accurate data capture. If you plan to scan small objects, a short-range scanner will give you better detail. For larger objects, like vehicles or rooms, you’ll need a scanner with a longer range. Choosing the right range ensures you get the best balance of detail and coverage for your specific projects.

Can mobile apps replace dedicated 3D scanners?

Mobile apps for 3D scanning have improved a lot and are great for quick, low-cost scans of simple objects. They use your smartphone’s camera and sensors to create 3D models. However, they can’t match the accuracy, detail, or speed of dedicated 3D scanners, especially for professional or industrial use. If you need high-quality results or plan to scan complex shapes, a dedicated 3D scanner is still the best choice.

What maintenance is required to keep a 3D scanner precise?

To keep your 3D scanner performing at its best, regular maintenance is key. This includes cleaning the lenses and sensors with a soft cloth, updating the firmware and software, and storing the device in a dust-free, dry environment. For professional models, periodic calibration may be necessary to maintain accuracy. Always follow the manufacturer’s care instructions to ensure long-lasting precision and reliability.