For years, I believed that hand-plucking chickens was simply part of the process—slow, messy, and exhausting. That belief changed the day I saw my first chicken plucker in action at a fellow homesteader’s farm. At first glance, the machine looked intimidating, almost like a piece of industrial machinery. But within minutes, it transformed what had always been a time-consuming chore into a smooth, efficient process. Whether you’re raising a small backyard flock or managing a larger poultry operation, the right chicken plucker can save you hours of labor while improving the quality and consistency of your results. In this guide, we’ll explore how these machines work, key features to consider before buying, and why a reliable chicken plucker is one of the smartest investments you can make for your homestead or farm.

Chicken Plucker Overview: From Folklore to Farmyard Essential

Long before electric chicken pluckers revolutionized backyard farming, removing feathers was a painstaking ritual that could make anyone reconsider their dinner plans. I learned this the hard way during my first attempt at processing chickens by hand—twenty-five minutes per bird left my fingers cramped and my patience thoroughly tested.

Traditional hand-plucking has been around for centuries, with farm families gathering to tackle this tedious chore together. The process involved scalding birds in hot water, then methodically pulling feathers by hand, one stubborn plume at a time. A good plucker turnsa dreaded chore into an afternoon breeze , as poultry expert Laura Kinsley puts it, and modern technology finally delivered on that promise.

How Electric Chicken Pluckers Changed Everything

The best chicken plucker models today use electric motors to spin drums lined with rubber fingers , dramatically reducing processing time from 20-30 minutes per bird to just 2-4 minutes. This breakthrough made home poultry processing accessible to ordinary backyard farmers like myself.

Popular brands such as Yardbird , Kitchener , and SuperHandy have made this technology affordable for home use chicken plucker applications, transforming what was once a dreaded weekend task into something almost enjoyable.

Tub-Style vs. Drum-Style: The Key Differences

Modern chicken pluckers come in two main configurations. Tub-style pluckers feature a stationary outer tub with a spinning bottom plate, while drum-style pluckers rotate the entire chamber. Both use the same principle—rubber fingers grab and pull feathers as the bird tumbles inside.

Most units feature stainless steel drums for durability, flexible rubber fingers for gentle feather removal, and water irrigation rings to wash away debris during processing. The capacity varies significantly, with some models handling single chickens while others accommodate small flocks.

My Comic First Attempt

During my inaugural chicken plucker experience, I made the rookie mistake of not properly securing the water hose connection. Water sprayed everywhere, feathers flew in unexpected directions, and I somehow ended up with a stray tail feather stuck in my hat. Despite the chaos, I was amazed at how clean and fast the finish was compared to hand-plucking.

The chicken plucker overview wouldn't be complete without acknowledging how electric models vastly improve speed and consistency while saving significant manual labor. What once required an entire afternoon can now be completed during a lunch break, making backyard poultry processing practical for busy families.

Key Features of Chicken Plucker: The Nuts and Bolts (and Rubber Fingers)

After testing multiple electric chicken plucker models, I've learned that the key features of chicken plucker designs can make or break your processing experience. Let me walk you through what really matters when you're evaluating these machines.

Motor Horsepower: What Actually Drives the Action?

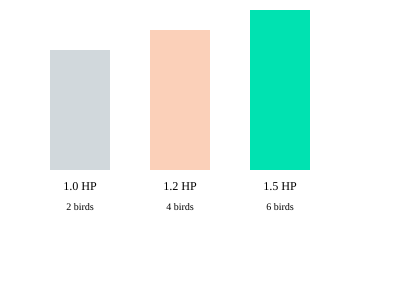

The motor power is your plucker's heartbeat. I've found that 1.0 HP motors work fine for small farm operations processing 2-3 birds at once. However, if you're planning to process more birds regularly, stepping up to 1.5+ HP makes a noticeable difference in performance and consistency.

Stainless Steel Drum : Your Foundation for Success

The stainless steel drum isn't just about looks – it's about durability and food safety. I've noticed that food-grade 304 stainless steel holds up much better than painted alternatives. This material resists corrosion and cleans easily, which is crucial when you're processing multiple birds.

Rubber Fingers: The Unsung Heroes

Those little rubber fingers do all the heavy lifting. Quality fingers provide gentle yet firm feather removal without damaging the skin. From my experience, good rubber fingers last about 100+ birds before needing replacement. The spacing and flexibility matter more than you might think.

Capacity and Water Systems

Most home models handle up to 6 chickens, like the popular Yardbird plucker. However, single-bird units work great for smaller operations.

The water irrigation ring is a game-changer I didn't appreciate initially. This built-in rinse system keeps feathers from clogging and makes cleanup much simpler.

'The right combination of motor, drum, and fingers makes or breaks the plucking experience.' – Simon Bracewell

Safety Features That Matter

Look for these essential safety elements:

GFCI protection for electrical safety

Automatic safety switches

Sturdy protective housing

Emergency stop mechanisms

These features protect both you and your investment, especially when working in wet conditions typical during processing.

Pros & Cons: The Honest Truth About Chicken Pluckers

After months of testing different models and reading countless customer reviews , I've learned that chicken pluckers aren't miracle machines—they're tools with real strengths and genuine drawbacks. Let me give you the unvarnished truth about what you can expect.

The Good News: Why Chicken Pluckers Shine

Time and Labor Savings Are Game-Changers

The biggest advantage hits you immediately. What used to take me 45 minutes per bird now takes less than 8 minutes. That's over 80% time reduction compared to manual plucking. As one satisfied customer, Greg Harmon, puts it: "I got my Sundays back after switching to a plucker. Money well spent."

Your Back Will Thank You

No more hunching over birds for hours. Most home use chicken pluckers work at standing height, eliminating the backache that plagued my processing days.

Consistent Feather Removal

Manual plucking always left patches I'd miss, especially around wings and thighs. Pluckers get nearly every feather in one go, producing cleaner-looking birds.

Less Mess (If You Choose Right)

Models with built-in water irrigation contain feathers better than dry plucking. The mess stays contained instead of floating around your workspace.

The Reality Check: Where Pluckers Fall Short

Initial Investment Hurts

Entry-level models start around $350, while premium units hit $700+. That's a significant upfront cost, especially if you only process a few birds annually.

One Size Doesn't Fit All Birds

Most pluckers excel with chickens but struggle with ducks or turkeys. The different feather types and skin thickness require technique adjustments—and sometimes different equipment entirely.

Size Surprises

I underestimated how bulky these machines are. My first plucker barely fit through my barn door. Measure your space before buying.

Noise Factor

Here's something customer reviews rarely mention: these things are loud. I learned this the hard way when I fired up my first plucker and startled every chicken within two blocks. My neighbors weren't thrilled either.

The Bottom Line on Pros and Cons

The pros and cons of chicken pluckers boil down to this: they're excellent time-savers that require significant upfront investment. If you process more than 20 birds yearly, the time savings justify the cost. For occasional use, the math gets trickier.

The sweet spot seems to be families processing 50+ birds annually or small farms doing regular batches. That's where the efficiency gains truly shine.

Who Should Actually Get a Chicken Plucker? (And Who Might Not Need One)

After months of research and testing, I've learned that the best chicken plucker isn't for everyone. Let me share some honest insights about who really benefits from these machines and who might want to stick with hand-plucking.

The Sweet Spot: Who Really Needs One

If you're processing 10 or more birds annually , a chicken plucker becomes a game-changer. As Christine Mains wisely told me:

"If you process more than a dozen birds a year, don't pluck by hand."

Backyard poultry processing enthusiasts who raise meat birds seasonally are perfect candidates. I watched my neighbor Sarah transform her twice-yearly processing day from a grueling 8-hour ordeal to a manageable 3-hour task with her drum plucker.

Small farm co-ops have found creative solutions too. Five families in my area split the cost of a quality plucker, sharing it throughout processing season. Each family saves money while still enjoying the time-saving benefits.

Physical Considerations Matter

Anyone with physical limitations should seriously consider a home use chicken plucker . Hand-plucking strains wrists, fingers, and shoulders. I've seen older farmers extend their processing years by switching to electric models.

The repetitive motion of manual plucking can aggravate arthritis and cause genuine discomfort. Electric pluckers eliminate this concern entirely.

Maybe Skip It If...

Processing just one or two birds yearly ? The investment probably doesn't make sense. Hand-plucking a couple chickens, while tedious, won't justify the cost or storage space.

Urban homesteaders with strict space limitations might also reconsider. These machines require dedicated storage and aren't exactly apartment-friendly.

The Middle Ground

Processing 5-10 birds annually puts you in the maybe category. Consider these factors:

Your budget flexibility

Available storage space

Physical comfort during processing

Time constraints on processing days

Some folks in this range invest in smaller, more affordable models or explore sharing arrangements with neighbors.

The beauty of chicken pluckers lies in their ability to transform an exhausting chore into a manageable task. Whether you're a dedicated backyard farmer or someone looking to make occasional processing more comfortable, understanding your specific needs helps determine if this investment makes sense for your situation.

How to Choose the Best Chicken Plucker For Your Flock

Finding the right chicken plucker buying guide starts with understanding your specific needs. As someone who learned this lesson the hard way with a bargain unit that leaked like a sieve, I can tell you that choosing wisely from the start saves both money and frustration.

Tub-Style vs. Drum: Which Suits Your Operation?

The first decision in any electric chicken plucker selection involves choosing between tub-style and drum models. Tub-style units handle 4-6 birds at once , making them perfect for larger flocks or processing days. Think of them as the washing machine of chicken pluckers – spacious and efficient for bulk work.

Drum-style pluckers, meanwhile, excel at handling 1-2 birds per batch. They're more compact and ideal for smaller homesteads or when you're processing birds gradually rather than all at once.

Motor Power and Performance Considerations

When evaluating motor power and performance , remember that horsepower directly impacts your success with larger birds like turkeys or mature roosters. I recommend going higher than you think you need – a more powerful motor handles tough jobs without straining, extending your equipment's lifespan significantly.

Consider your plucking capacity versus your actual flock size. If you raise 20 birds annually but process them in groups of 4-5, a smaller drum unit might serve you better than a large tub model that sits mostly empty.

Material Quality and Durability

Material selection matters enormously for longevity and food safety. Look for food-grade stainless steel construction, especially for parts contacting your birds. Brands like Yardbird, Kitchener, and SuperHandy each offer different approaches to durability, with varying quirks in their designs.

Cleaning Features That Actually Matter

Easy cleanup transforms your processing experience from dreaded chore to manageable task. Water system integration and quick-release drum features speed up post-processing cleanup considerably. Removable parts and hose-down capability aren't just conveniences – they're necessities for maintaining food safety standards.

"Your ideal plucker is the one you don't dread dragging out." – Sam Tiller

Warranty and Long-Term Value

Standard warranties typically run 1-2 years , but warranty length varies significantly by brand. This coverage becomes crucial when you consider that motor repairs often cost more than buying a new budget unit. Factor in customer support quality and parts availability when weighing your options – these elements determine your equipment's practical lifespan far more than initial purchase price.

Keep It Running: Maintenance, Care, and My DIY Repairs

'Maintenance is the quiet hero—neglect it and the plucker turns on you.' – Jerry Mosby

I learned this lesson the hard way during my second season. After processing about 80 birds, I ignored the warning signs—squeaky belt, sluggish drum rotation, and feathers sticking everywhere. Then disaster struck: the motor belt snapped right in the middle of my biggest harvest day.

Regular Deep-Cleaning for Peak Performance

For chicken plucker maintenance , I clean after every 1-2 uses. The stainless steel drums and rubber fingers need thorough scrubbing to prevent buildup and odor. I use warm soapy water and a stiff brush, paying extra attention to feather residue stuck between the rubber fingers.

The removable parts make cleaning so much easier. I pop out the drum, remove the finger assembly, and clean each component separately. This prevents grease and feather particles from hardening into stubborn gunk.

When to Replace Those Rubber Fingers

After processing 100-200 birds, those rubber fingers start losing their grip. I noticed mine becoming less effective around the 120-bird mark—feathers weren't coming off as cleanly. The replacement process is straightforward: unscrew the old fingers, clean the mounting holes, and install new ones.

Pro tip: Replace all fingers at once, even if only some look worn. Mixing old and new fingers creates uneven plucking.

Motor Care and Belt Inspections

Every 50-60 birds, I perform motor maintenance. I check for overheating by feeling the motor housing after use—it should be warm, not burning hot. I inspect the belt for cracks, fraying, or stretching.

My DIY disaster taught me everything about belt replacement. When mine snapped, I temporarily rigged it with duct tape and a spare belt from my old lawnmower. It worked for three birds before I got the proper replacement!

Water Systems and Storage Hacks

I drain all water from feather chutes and spray systems after each use. Standing water breeds bacteria and can freeze in winter, cracking pipes. For the durable build to last, I store my plucker in a dry, covered shed—never outside where humidity can rust steel components and damage electrical connections.

Annual Deep Maintenance

Once yearly, I completely disassemble the cleaning features , inspect all moving parts, and lubricate bearings. This routine care greatly extends product life and efficiency. I check electrical connections, test the motor under load, and replace any worn gaskets or seals.

Trust me, spending two hours on annual maintenance beats dealing with a broken plucker during processing season. Regular care keeps your investment running smoothly for years.

Final Verdict: Is a Chicken Plucker Really Worth It?

After months of testing different models and countless chickens processed, I can finally answer this question with complete honesty. For most serious poultry keepers, a chicken plucker is absolutely worth the investment . The time savings alone – up to 80% compared to manual plucking – makes it a game-changer.

Let me share a moment that sealed the deal for me. Last Sunday, I sat down to enjoy my first home-raised chicken dinner in months without finding a single stubborn feather on my plate. That simple pleasure made every dollar spent feel justified.

Who Should Buy a Chicken Plucker

If you process more than five birds per year, you're a prime candidate. Small farm operations and backyard chicken keepers who value their time will see immediate benefits. Co-op groups sharing equipment costs make even premium models affordable.

However, if you only process one or two birds annually, the investment might not make financial sense. At $4-6 per bird for professional processing, you'd need years to break even.

My Top Buying Tip

Here's my strongest recommendation: try before you buy if possible. Many farm supply stores offer demonstrations, and some co-ops rent equipment. This hands-on experience prevents costly mistakes and helps you choose the right size.

"Once you've plucked electric, you never go back." – Priscilla Turner

Priscilla's words ring true. Electric models truly are game-changers for serious poultry keepers, offering consistent results that manual methods simply cannot match.

My Surprising Favorite Feature

Here's what I didn't expect to love most: the cleanup simplicity . I thought speed would be the biggest benefit, but having minimal mess afterward changed my entire processing routine. No more hours scrubbing feathers from every surface.

Final Recommendations by User Type

Backyard keepers (5-20 birds/year): Tabletop drum plucker

Small farms (20-100 birds/year): Medium-capacity electric model

Co-ops or large operations: Industrial-grade stainless steel units

The bottom line? If chicken processing is part of your regular routine, a quality plucker transforms a dreaded chore into manageable work. The initial investment pays dividends in saved time, reduced labor, and significantly less mess. After experiencing the difference firsthand, I honestly can't imagine returning to manual plucking methods.

Frequently Asked Questions: Chicken Plucker Quirks, Tips & Troubles

Does a chicken plucker work with ducks and turkeys?

Here's where size matters. Most chicken pluckers handle ducks beautifully since they're similar in size. However, turkeys present a challenge. Standard drum pluckers often struggle with full-grown turkeys due to size constraints. I learned this the hard way during my first Thanksgiving prep. If you regularly process larger birds, invest in a plucker specifically designed for turkey capacity.

What's the secret to faster, gentler feather removal?

The scalding process is absolutely crucial for feather removal efficiency . I can't stress this enough: proper preparation makes all the difference.

'A plucker is only as good as your prep.' – Elisa Cortez

Heat water to 140°F–150°F and scald birds for 30–60 seconds. This temperature loosens feathers without cooking the meat. Skip this step, and your rubber fingers will work overtime while potentially damaging the skin.

How noisy are these things really?

Let's be honest – chicken pluckers aren't whisper-quiet. Drum models typically generate more noise than tabletop versions due to their larger motors. The sound resembles a washing machine on spin cycle. If you live close to neighbors, consider processing during reasonable hours. Some users build simple sound barriers or operate pluckers in enclosed spaces to minimize noise complaints.

Can I use it with just one bird?

Absolutely, though it might feel like overkill. Tabletop pluckers work perfectly for single birds, while drum pluckers can handle anywhere from one to multiple chickens simultaneously. For occasional use with individual birds, smaller models prove more practical and economical. The key is matching plucker size to your typical processing volume.

What parts wear out most quickly?

Based on customer reviews and my experience, rubber fingers take the biggest beating. These flexible components gradually lose their grip and tear with regular use. Expect to replace them every 50-100 birds, depending on usage frequency. Replacement rubber finger packs cost $20–$35 on average.

Drive belts are the second most common replacement item, especially on drum models. They stretch and wear over time, reducing efficiency. Motors typically last years with proper maintenance, but switches and electrical components may need attention sooner.

Pro tip: buy replacement parts when you purchase your plucker. Having spare rubber fingers on hand prevents processing delays when wear becomes apparent. Most manufacturers sell maintenance kits that include commonly replaced components at discounted prices compared to individual part purchases.